Our MultiSystem switching systems can be built with any number of inputs,

outputs and stop controls. The system is configured in software which allows

the for an extremely flexible structure and straightforward building blocks.

A location is built from a processor, a plane (to put the cards on) and a

choice of positive or negative polarity, input or output cards. The system

is controlled by software which is loaded into each processor.

The MultiSystem is built around high specification industrial processors that

run a custom operating system designed for high speed real time processing.

The total boot time is about 6 seconds and so the system is ready to run

before the wind is up.

Communication between locations is by CAT5 100BaseT Ethernet cabling.

Although the protocols running on the cable are fully compatible with an

Ethernet system we only support a closed network that is solely for

MultiSystem use, this is because we can only

guarantee performance if we know the amount of traffic on the network. It is

possible to use a 802.11 Wireless network but again we cannot guarantee it

will be to our performance requirements due to an inability to control

external interference.

Wiring

Solid State pioneered the use of punch blocks in organ building, however we

selected a high performance connector from a German manufacturer called

Krone that has been in use in the European telecoms industry for 80 years

and more recently was adopted for internet

connections in large office buildings around the world. It has been used by

us in organ building since 1991.

Power

MultiSystem operates between 12 to 36-volt as standard. The system itself

uses less than 1 Amp to operate, however care must be taken in providing

adequate current to switch the organ loads.

Outputs -

Output modules provide 16 outputs per module. They are provided with Krone

connectors to punch the wires directly to them avoiding an extra connector

and hence increasing reliability. The module has built in suppression.

- Negative Output - 0.75A maximum rated. Equivalent to 16 Ohms at 12V or

32 Ohms at 24V.

- Heavy Duty Negative Output - 1.4A maximum rated. Equivalent to 9 Ohms at

12V or 18 Ohms at 24V.

- Positive Output - 0.1A maximum rated. Equivalent to 120 Ohms at 12V or

240 Ohms at 24V.

- Heavy Duty Positive Output - 1.4A maximum rated. Equiv to 9 Ohms at 12V

or 18 Ohms at 24V.

Inputs -

Positive Input - A high resistance input with built in surge protection

and debouncing for dirty key contacts. The module loads the contact by

less than 10mA and will accept inputs from 10 to 36V.

- Negative Input - The same specification but an alternate polarity.

Can I copy piston settings from one memory level to another?

Yes, that is easily done using Copy, Paste and Clear.

Can I lock my memory levels?

Yes, with a lock switch installed at the console, or with a personal PIN code

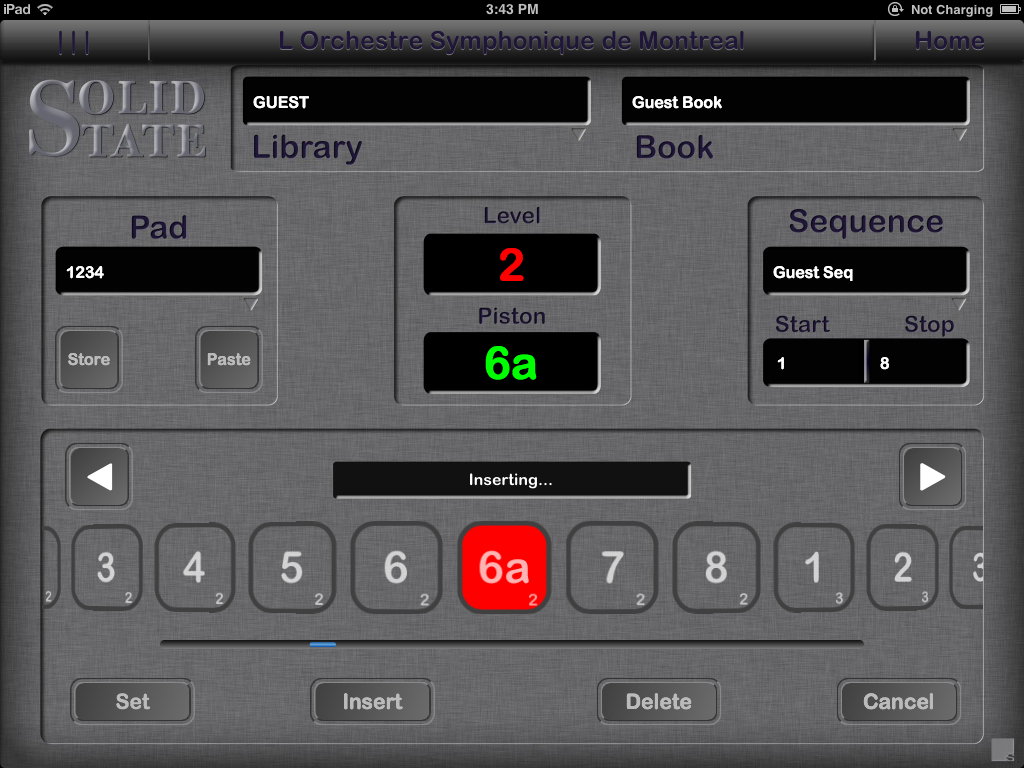

Can I insert additional steps into the Sequencer pattern?

A standard Stepper progresses through the General pistons in order using Next and Previous.

Most organists find this to be simplest system to use, but an Advanced Sequencer is also available.

With Advanced Sequencer, addition settings can Inserted and Deleted into the sequence.

Can divisional pistons swap places with the keyboards when Manual Transfer is engaged?

Yes, this can be configured in any way that you like. With a typical Great/Choir transfer,

the standard practice is to swap the Great and Choir divisional pistons and the Gt/Ped and Ch/Ped

reverser thumb pistons with the Transfer. Toe pistons are unaffected. However, we can set it up in

any other way that you prefer. A common request is for coupler reverser pistons not to be included.

If my memory levels are controlled by a rotary switch, can I include a sequencer too?

Sadly no, the sequencer cannot change the position of a mechanical rotary switch, so the system

will remain on the same memory level until the rotary switch is changed by hand.

Sequencers are easy to include with our digital control panels.

Can I have separate General and Divisional memory levels?

Absolutely! This is standard practice in larger U.K. organs, and we can include it in any system.

Can stops be set automatically to cancel other stops?

Yes, although this is not commonly asked for, it is certainly possible to do it

Can I jump quickly to another memory level?

Yes, consoles can be equipped with +1, -1, +10, -10, +100 and -100 buttons and/or, with the

Goto feature, you can press and hold General Cancel and enter the memory level using the

General pistons. You need at least 10 General pistons for this to work.

Can I put individual stops on reverser pistons?

Yes, when the system is configured, individual stops, such as a Pedal 32’ stop, can be set

onto a reversible piston. We also offer reverser pistons that can be set by the organist to control any one stop.

Can I add pedal stops to manual pistons?

A typical Piston Coupler will couple the pistons of one division to the pistons of another.

The most commonly used piston coupler is Great and Pedal Pistons Coupled, sometimes known as

Great and Pedal Combinations Coupled. And, these pistons couplers can be configured in

two ways, so that they work in both directions with both sets of pistons coupling to one

another, or so that only one set of pistons also controls another.

With Scope Modifiers, stops on one division can temporarily be made available to be set on the

pistons of another division. This is independent of what is set to the pistons of the other divisions.

For example, with Pedal on Swell Pistons, Pedal stops can be added to the Swell pistons, which the

Pedal pistons themselves will remain unaltered. We can include multiple Scope Modifiers in the same system.

Can I change which stops are controlled by which pistons?

Yes and No. Most often, the scope of pistons (which stops are assigned to each piston)

is set by the organ technician when the system is configured at installation. But, using the

Scope feature, your technician can change the scope of pistons if you’d like. Or, with a

Scope piston at the console, organists can change the scope of pistons themselves.

This is recommended only for experienced users.

Can I move swell/expression boxes to different expression shoes/pedals?

Yes. Using expression couplers you can assign any expression box to any expression shoe/pedal.

For the most complex systems, Expression Matrix allows any box to be attached to any pedal with a

grid of controls at the console, and settings can be saved on General pistons.

Please let us know if you have additional questions. We can create more or less any control that you can imagine. Please feel free to ask.